Fab labs and makerspaces, pillars of creativity and innovation, embody dynamic spaces dedicated to exploration and materialization of ideas. These collaborative spaces stand out for the richness of their equipment, providing privileged access to a variety of digital fabrication machines. These machines aim to transform concepts and ideas into tangible projects. However, beyond merely providing access to these tools, managing them poses a major challenge.

Fostering innovation through well-equipped spaces and adequate training

At the heart of fab labs' activity lies the establishment of dynamic spaces dedicated to creativity and innovation. These places stand out for providing a wide range of digital fabrication machines, catalytic tools for materializing everyone's ideas. The main challenge of these machines is to allow fab lab members to explore, create, and prototype projects, whether they are technological innovations, everyday objects, or artistic creations. The goal is to encourage free and inventive experimentation, giving everyone the opportunity to bring their ideas to life through diverse and accessible tools.

The use of these machines often accompanies initial training, essential to ensure safe and effective operation. Through these training sessions and the provision of various machines, participants acquire the confidence and know-how necessary to realize their most creative ideas.

Creation of a project in the field of robotics

Common machines in fablabs

Within fablabs, certain machines stand out as essential. They are present in most fablabs, including:

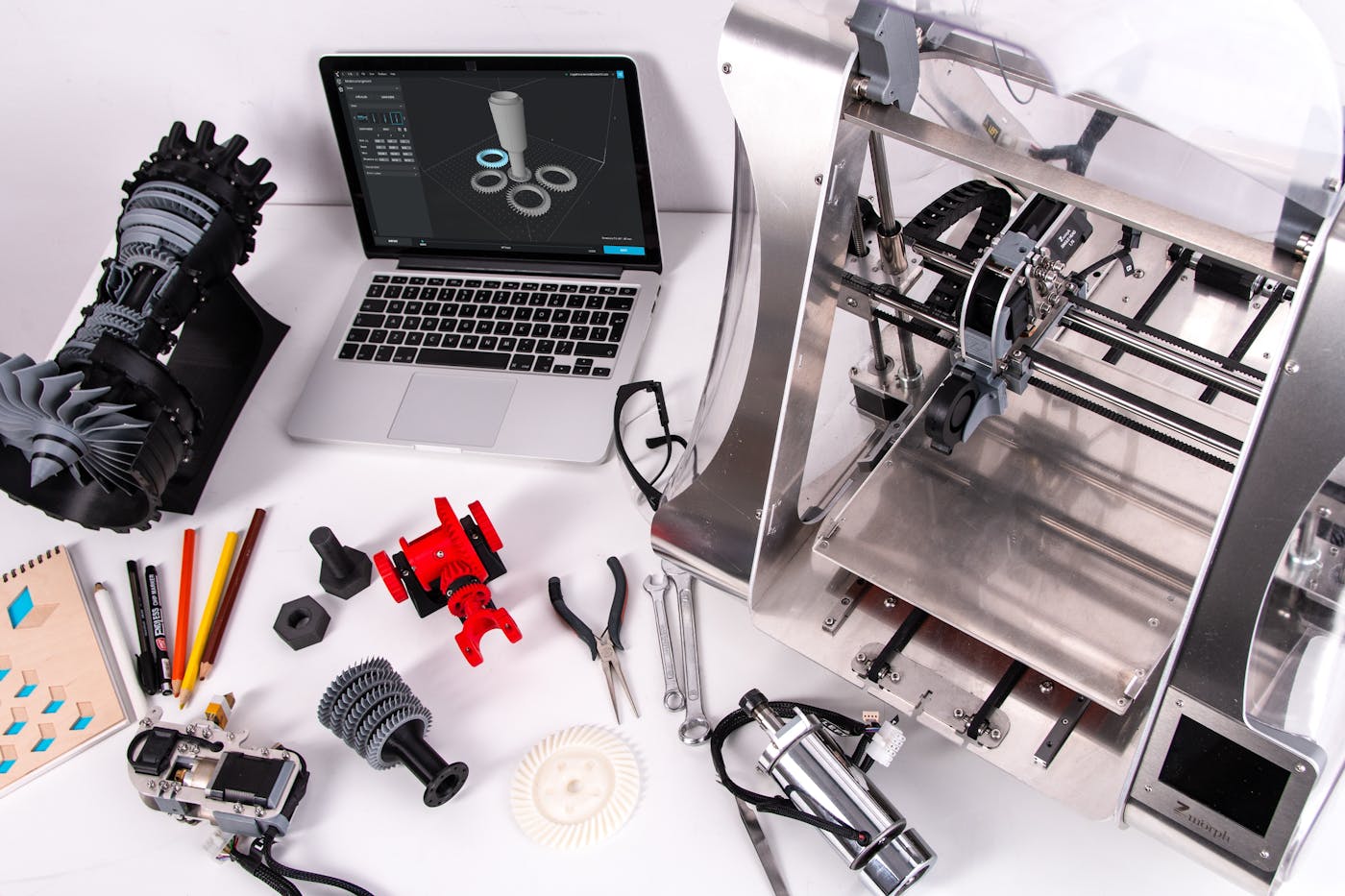

1. 3D Printer

The 3D printer is a true icon of fablabs. It allows the fabrication of three-dimensional objects from digital models. This machine opens up a wide range of possibilities, from prototyping objects to complex artistic creations. Examples of creations include mechanical parts, architectural models, decorative objects, customized prosthetics, and even innovative jewelry.

Focus on the 3D printer, available at N°4, the fablab of Pays de Lorient, in France: : https://fablab-lorient.bzh/#!/machines/imprimante-3d-resine-formlabs-form-2

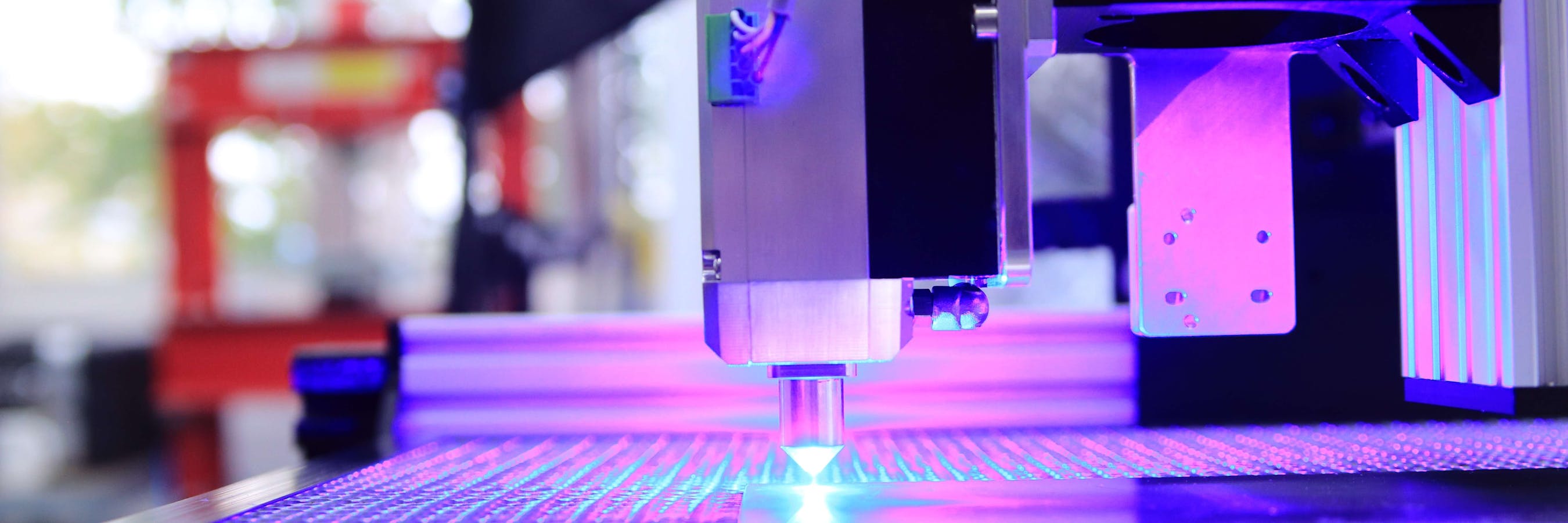

2. Laser cutter

The laser cutter is a versatile machine capable of cutting and engraving with great precision on various materials, such as wood, plastic, cardboard, or fabric. It is widely used for creating personalized objects, architectural models, puzzles, lettering, decorative cards, engraved patterns on wood, and much more.

Discover the laser cutter at Fablab la Verrière, managed by the association La Fabrique de l’Espoir in Montreuil: https://fabmanager.fablab-laverriere.org/#!/machines/decoupeuse-laser-g1008

3. CNC Milling Machine

The CNC milling machine is a precise equipment allowing the machining of parts by removing material from a block of materials. Achievements include control panels, mechanical parts, molds for manufacturing, or even complex sculptures. Its popularity lies in its ability to produce complex mechanical parts with great precision, thus transforming concepts into tangible products.

Preview of the digital milling machine, available at Roselab, the shared fabrication laboratory of La Cité in Toulouse: https://roselab.fab-manager.com/#!/machines/fraiseuse-numerique

Fablab Equipment Examples

Specialized Machines in Specific Domains

Beyond common machines, some makerspaces offer specialized equipment tailored to specific domains. These machines unlock creativity in targeted sectors such as apparel.

This is the case with the fablab at the French Institute of Textile and Clothing (IFTH) in Paris. It is a technical platform providing services to fashion professionals aiming to rely on eco-friendly and innovative manufacturing. IFTH offers highly specialized textile machines such as a texture scanner or a covering machine: https://lelab.ifth.org/#!/

At Techshop Lille, you can also find machines dedicated to working with ceramics or metal: https://fabmanager.univ-catholille.fr/#!/machines

An Issue: Managing Tools and Machines in Fablabs

Providing access to digital fabrication machines is a crucial first step, but ensuring their fair and optimal use is a critical task to maintain the operation of the space.

The primary challenge for fablabs lies in efficiently managing reservations for their array of machines. The diversity of tools and varying member demand for their use makes a well-organized reservation system imperative. Poor reservation management can lead to usage conflicts, project delays, or even underutilization or overload of machines. This can negatively impact productivity, member satisfaction, and the fablab's profitability.

Online management solutions like Fabmanager play a significant role in addressing these challenges. These tools provide a centralized platform for members to check machine availability and reserve time slots for their use, enhancing the user experience. This automated reservation management also promotes fair allocation of machine usage time, reduces potential conflicts, and optimizes the fablab's resource utilization.

By providing access to digital fabrication tools and emphasizing optimal resource management, fablabs create an environment conducive to innovation. Through this combination, these spaces foster a culture of creativity where ideas come to life. Fablabs continue to nurture curiosity, stimulating the imagination of individuals and enabling ideas to materialize.

Simplify your day-to-day management

Let us host Fab Manager for you, choose the Cloud offer that suits you.

Start in the cloud